It is entirely automatic in action and thus the man-power requirement is very low.Ģ. B : Flow sheet for continuous vacuum filtration Advantages of Rotary drum filter :ġ. Usually, one-third of the cycle is used for filtration, one-half for washing and air drying and one-sixth for cake removal.įig.Once the cake is removed from the drum sector, it re-enters the slurry and the cycle is repeated. A little air is blown in under the cloth to aid the removal of the cake. After the cake of solids has been sucked as dry as possible, vacuum is cut off and the cake is removed by scrapping it off using a adjustable doctor's knife. After washing, the cake enters into a drying zone as the drum rotates where the cake is partially dried by sucking air through the cake of solids. The wash liquid leaves the filter through the rotary valve and is collected separately in a separate tank. As the portion of the drum on which the cake is formed comes out of the slurry, the cake is washed by spraying wash liquid.The filtrate from the compartment then goes to a filtrate collecting tank through the internal pipe and rotary valve. With higher speeds, thinner cake will be formed and consequently, high rate of filtration will be achieved. Because of this, the liquid (filtrate) is sucked into the compartment and solids get deposited on the cloth to form a cake of the desired thickness which can be regulated by adjusting the speed of the drum. Vacuum is then applied to the portion of drum which is submerged in the slurry through the rotary valve.

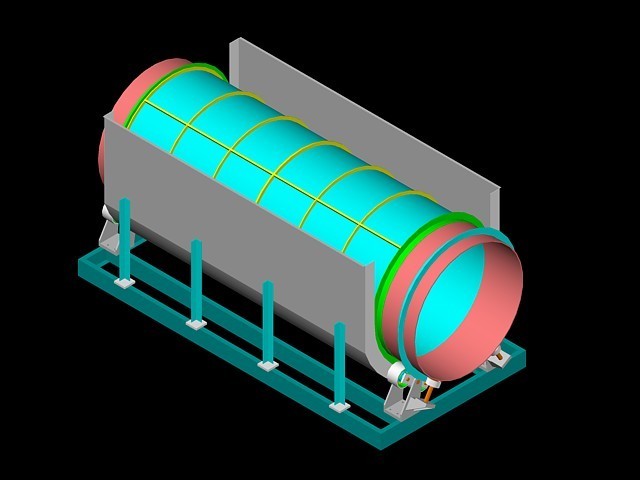

It consists essentially of a cylindrical sheet metal drum mounted horizontally. In this filter filtration, washing, partial drying and discharge of cake all take place automatically.

Besides, their competitive & cheap price of Rotary Drum Filter factory would get you an edge in your own market. If you are interested in China Rotary Drum Filter, You will be amazed by the variety of the product choices such as water treatment, water filter, drum filter. Our China manufacturers & suppliers will provide a full-service to keep you up and running and meet your unique equipment requirements. With hundreds of thousands of products to choose from and an ever growing product range, your industrial equipment needs are sure to be met here.

0 kommentar(er)

0 kommentar(er)